Thrus rubber slurry sentinam manufacturer de Sina

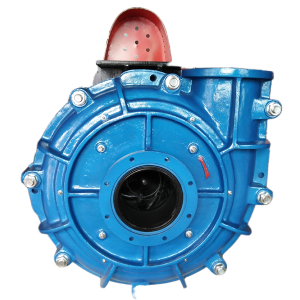

Thrus rubber eidem slurry soleatSunt similis ah metallum instruxit slurry sentinam in structuram. Pelagus differentia inter AH et Thrus est materia madefactum partibus, quae sunt naturalia Flexilis, synthetica Flexilis vel gerunt, repugnans fricatores. Thrus rubber eidem slurry pumps magis idoneam delivering fortis mordax vel abrasive slurries parvi particula magnitudine sine acuti marginibus.

Design Features:

√ graves officium constructione per-fulmen consilium praebet otium of sustentacionem et minimal downtime.

√ Ductile ferrum plene lined armamentis praebet diuturnitatem, vires, salus, et diu servitium vitae.

√ magna diametro, tardus conversionem, princeps efficientiam impellers disposito ad consequi maximum gerunt vitam et humilis operating costs.

√ magna, aperta internum locis disposito ad redigendum interna velocitates, maximize gerunt vitam et inferioribus operating costs.

√ crassa elastomer aut mixturae fulmine-in liners providere superior corrosio resistentia plus offer otium liner mutatio, et convertit ad reducere altiore sustentacionem costs et maximize gerunt vitae.

√ minimal hastili / impulsor overhang reduces hastile deflectit et crescit stipare vitae.

√ cartridge-style afferentem Conventum permittit ad sustentationem in mundum environment sine remotionem de slurry sentinam, unde in certa operatio et longum differentur afferentem vitam.

√ uncto vel oleum lubricatae ferre conventus options offer otium of sustentacionem et reducitur downtime.

√ libitum aridam currit SACCHE sigillum reduces vel excludit rubor aquae requisita.

√ effective expulser proponit stipare vitae dum reducendo vel eliminating rubor aquae postulationem.

√ Concutabilitate Sigillo - plena Flush, humilis fluxus, centrifuga, aut mechanica signacula potest esse aptavit ad quis amplitudo slurry sentinam.

Thrus Pinces perficientur parametri thr rubber euisined slurry:

| Exemplar | Max. Potentia (KW) | Materies | Patet aqua perficientur | Impuller Vane No. | |||||

| Liner | Impuller | Capacity Q (M3 / h) | Caput h (M) | Celeritate n (RPM) | EFF. η (%) | Npsh (M) | |||

| 1.5 / 1b-Thr | 15 | Flexilis | Flexilis | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 2-4 | 3 |

| II / 1.5B, Thr | 15 | Flexilis | Flexilis | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 3.5-8 | 5 |

| III / 2c-thr | 30 | Flexilis | Flexilis | 36-75.6 | 13-39 | 1300-2100 | 55 | 2-4 | 5 |

| IV / 3c, thr | 30 | Flexilis | Flexilis | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 5 |

| IV / 3D, Thr | 60 | Flexilis | Flexilis | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 5 |

| VI / 4d, thr | 60 | Flexilis | Flexilis | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 5 |

| VI / 4e-thr | CXX | Flexilis | Flexilis | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 5 |

| VIII / 6e-thr | CXX | Flexilis | Flexilis | 324-720 | 7-49 | 400-1000 | 65 | 5-10 | 5 |

| VIII / 6r-thr | CCC | Flexilis | Flexilis | 324-720 | 7-49 | 400-1000 | 65 | 5-10 | 5 |

| X / 8st, Thr | DLX | Flexilis | Flexilis | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | 5 |

| X / 8e-m | CXX | Flexilis | Flexilis | 540-1188 | 10-42 | 500-900 | 79 | 5-9 | 5 |

| XII / 10th, thr | DLX | Flexilis | Flexilis | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | 5 |

| XIV / 12th, thr | DLX | Flexilis | Flexilis | 1152-2520 | 13-44 | 300-500 | 79 | 3-8 | 5 |

| XVI / 14, thr | DLX | Flexilis | Flexilis | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 5 |

| XVIII / 16TU, Thr | MCC | Flexilis | Flexilis | 2160-5040 | 8-66 | 200-500 | 80 | 4.5-9 | 5 |

| XX / 18tu, thr | MCC | Flexilis | Flexilis | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 5 |

Thrus rubber Lined Slurry Pumps Applications:

THR series rubber slurry pumps are widely used in Mineral processing, Ball mill discharge, Bottom/fly ash, lime grinding, Coal, Coarse sand, Coarse tailings, Dredging, FGD, Fine tailings, Cyclone feed, Flotation, Heavy media, Minerals concentrate, Mineral sands, Ni acid slurry, Oil sands, Tallings, Phosphoric acid, Phosphate matrix, Process chemical, pulpam et charta, virga molendini defluxiones, sag molendini defluxiones, infectum crushers etc.

* Thrus rubber angusta slurry pumps et parcit non convertitur cum Warman®Thrus rubber luted slurry soleat et parcit.

Th cantaret cantilevered, horizontalis, centrifuga Slurry sentinam materia:

| Material Code | Materia descriptio | Applicationem components |

| A05 | XXIII% -30% cr album ferrum | Impeller, liners, expuller, expullis anulus, sagina arca, thurhatbush, artus laminam liner inserta |

| A07 | XIV% -18% Cf albus ferrum | Impleller, liners |

| A49 | XXVII% -29% C low Carbon White ferrum | Impleller, liners |

| A33 | XXXIII% C. erosions & corrosio resistentia alba ferrum | Impleller, liners |

| R55 | Naturalis Flexilis | Impleller, liners |

| R33 | Naturalis Flexilis | Impleller, liners |

| R26 | Naturalis Flexilis | Impleller, liners |

| R08 | Naturalis Flexilis | Impleller, liners |

| U01 | Polyurethane | Impleller, liners |

| G01 | Ferrum | Artus laminam, operimentum laminam, expullis, expullis anulus, ferre domum, base |

| D21 | Ferrum | Artus laminam, operimentum laminam, portantes domum, base |

| E05 | Carbon Steel | Hastulus |

| C21 | Aliquam ferro, 4Cr13 | Shaft sleeve, CORNO anulus, LORNER RES RES SPIRITOR, Neck Ring, Glandulae Bulla |

| C22 | Immaculatam ferro, 304ss | Shaft sleeve, CORNO anulus, LORNER RES RES SPIRITOR, Neck Ring, Glandulae Bulla |

| C23 | Immaculatam ferro, 316ss | Shaft sleeve, CORNO anulus, LORNER RES RES SPIRITOR, Neck Ring, Glandulae Bulla |

| S21 | Butyl Flexilis | Iuncturam annulos, iuncturam signacula |

| S01 | EPDM Flexilis | Iuncturam annulos, iuncturam signacula |

| S10 | Nitrile | Iuncturam annulos, iuncturam signacula |

| S31 | Hypo | Impulsor, liners, expullis anulus, expullis, iuncturam annulos, iuncturam signacula |

| S44 / K S42 | Neoprene | Impulser, liners, iuncturam annulos, iuncturam signacula |

| S50 | Viton | Iuncturam annulos, iuncturam signacula |